DIGITAL PLANNED MAINTENANCE

CENTRALIZED MAINTENANCE MANAGEMENT SYSTEM

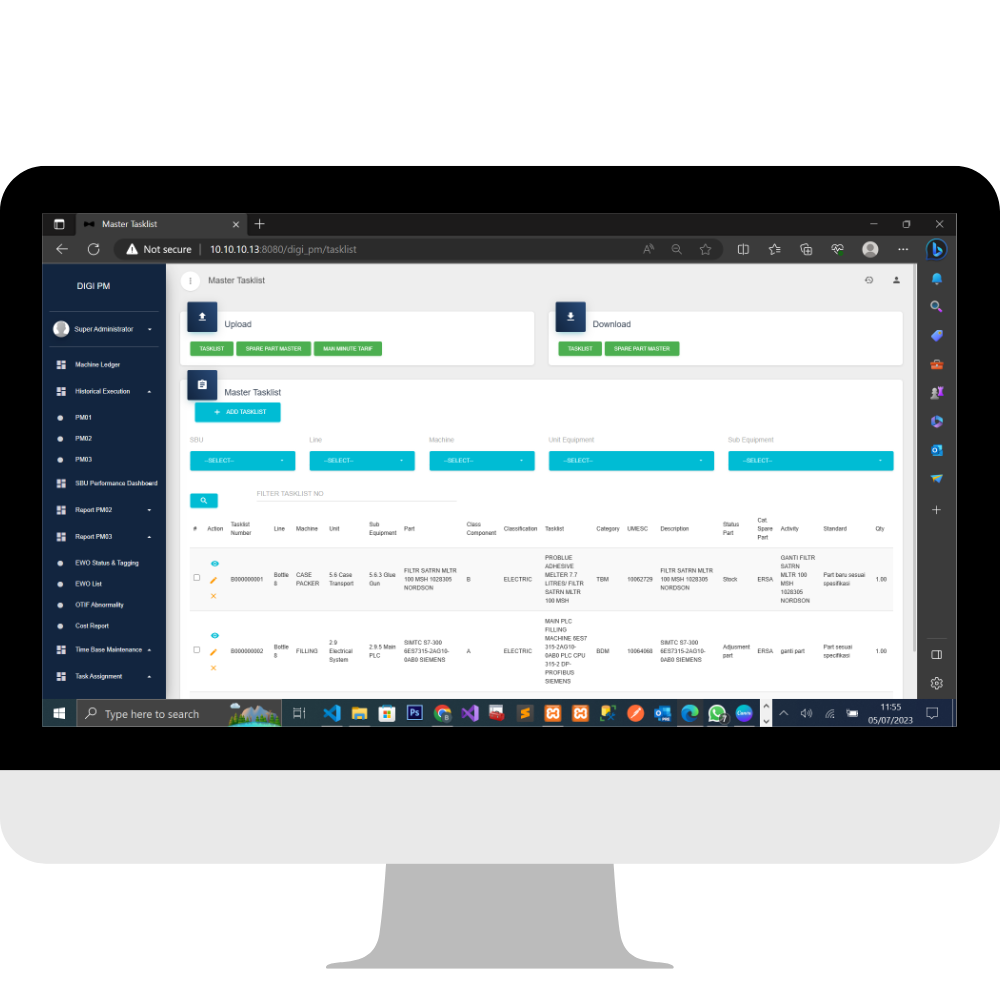

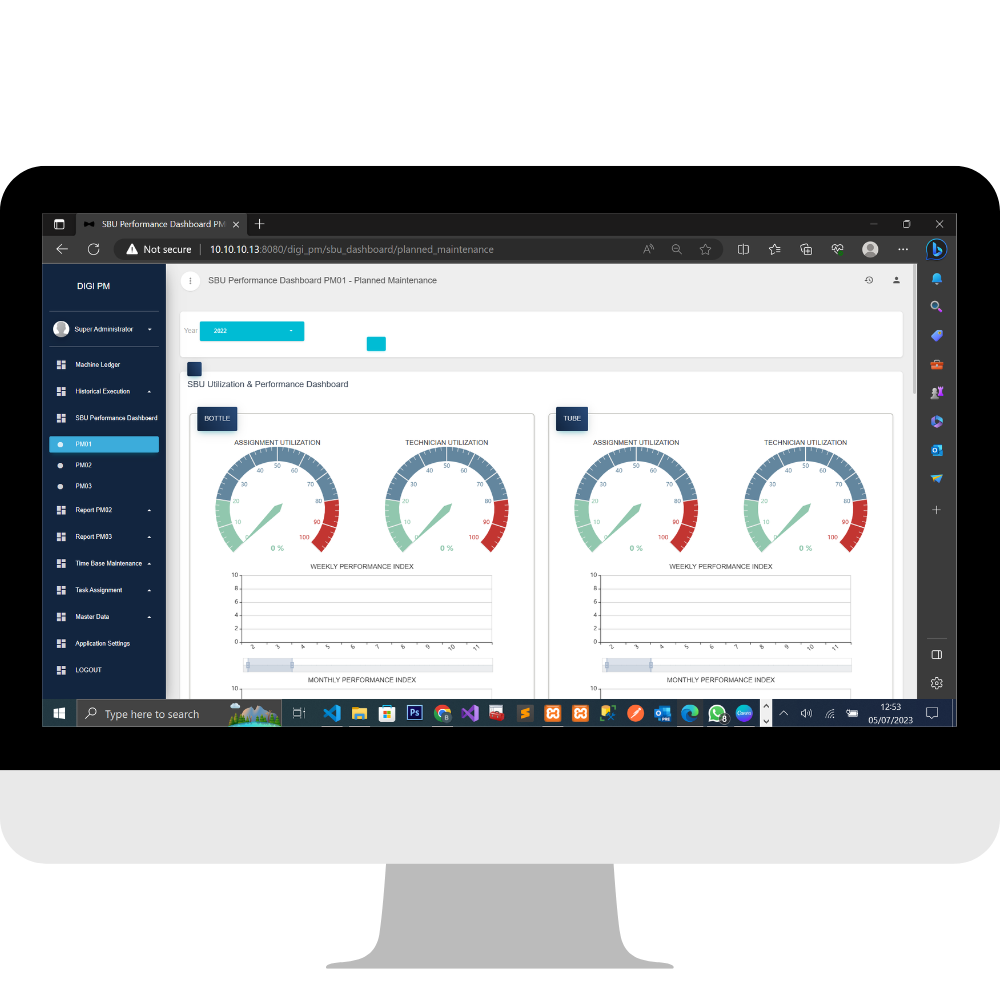

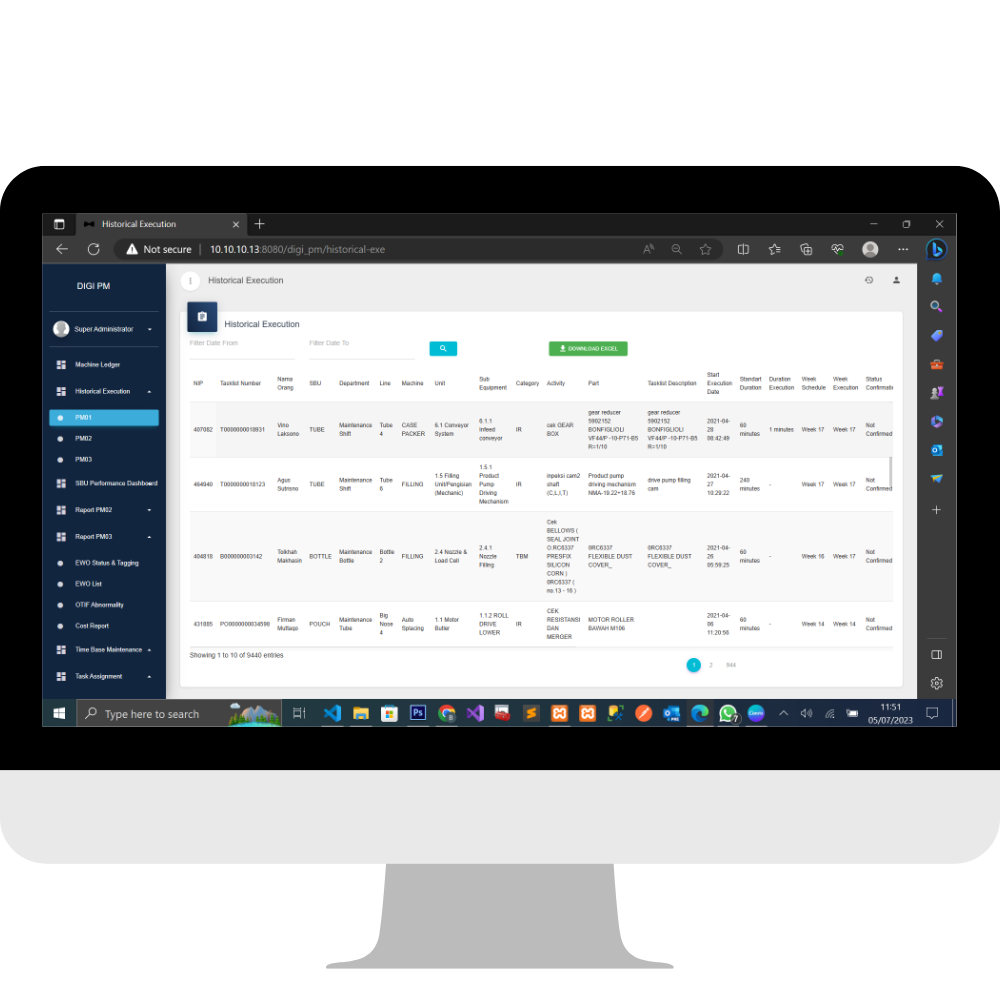

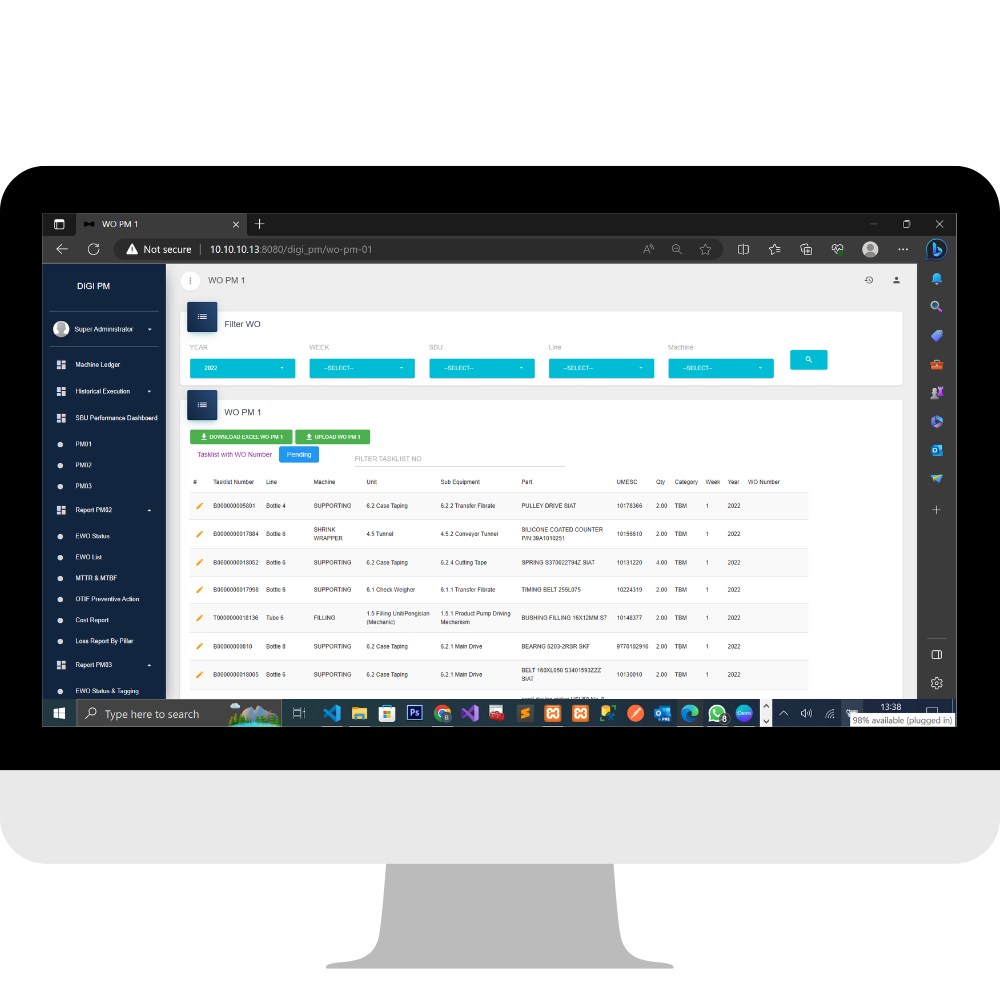

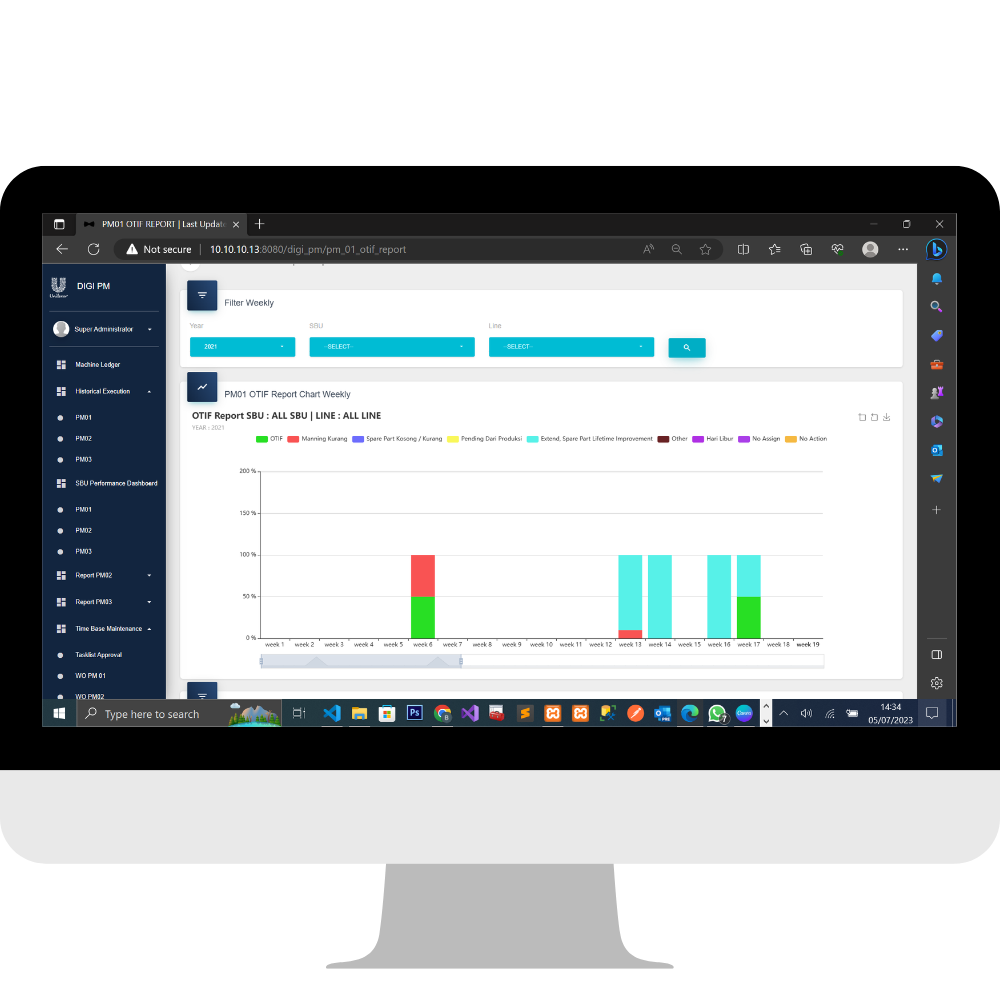

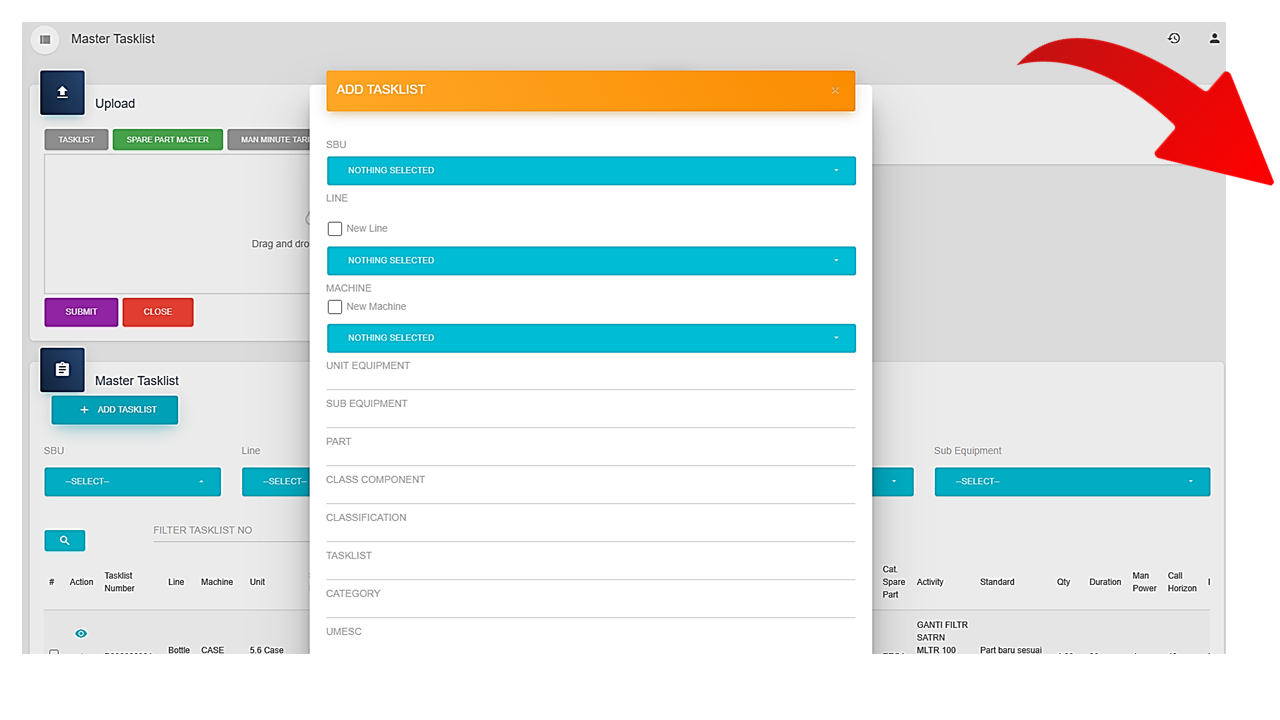

Tasklist management by detailed parameters to automatic roll-up the schedule for technician

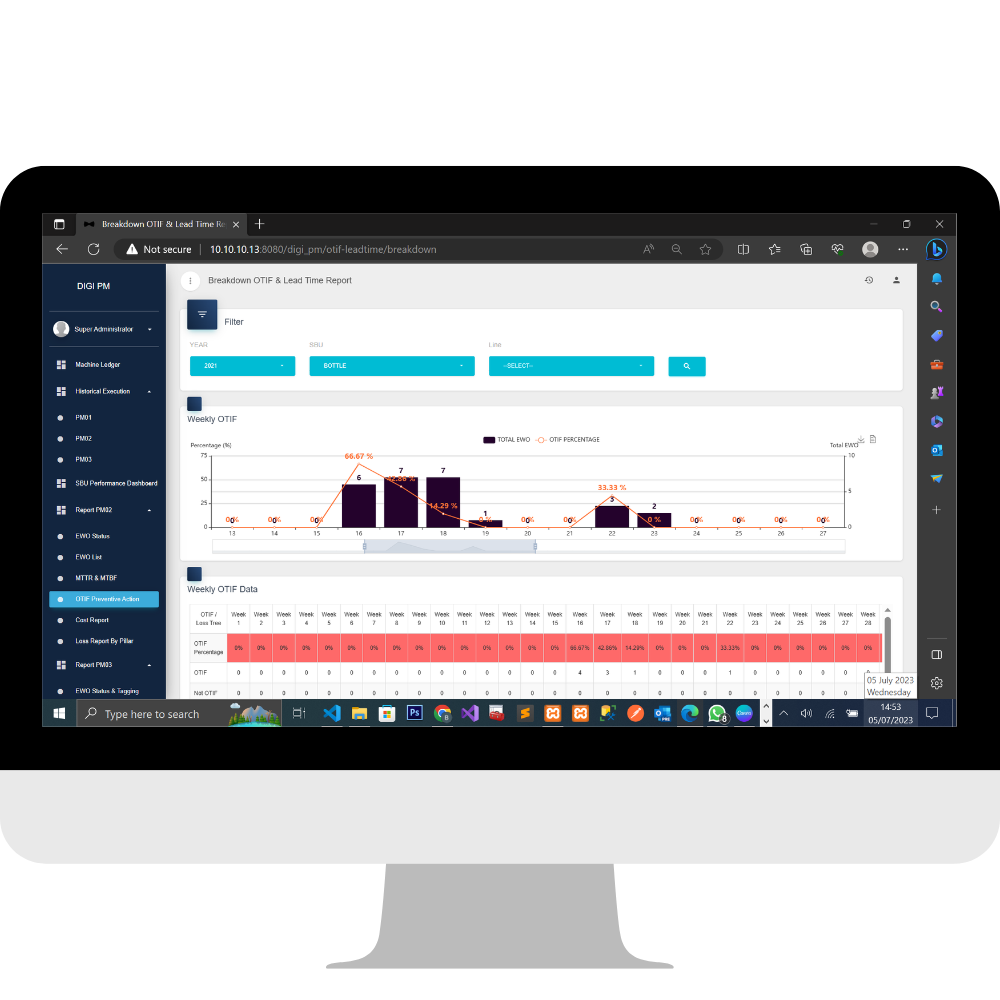

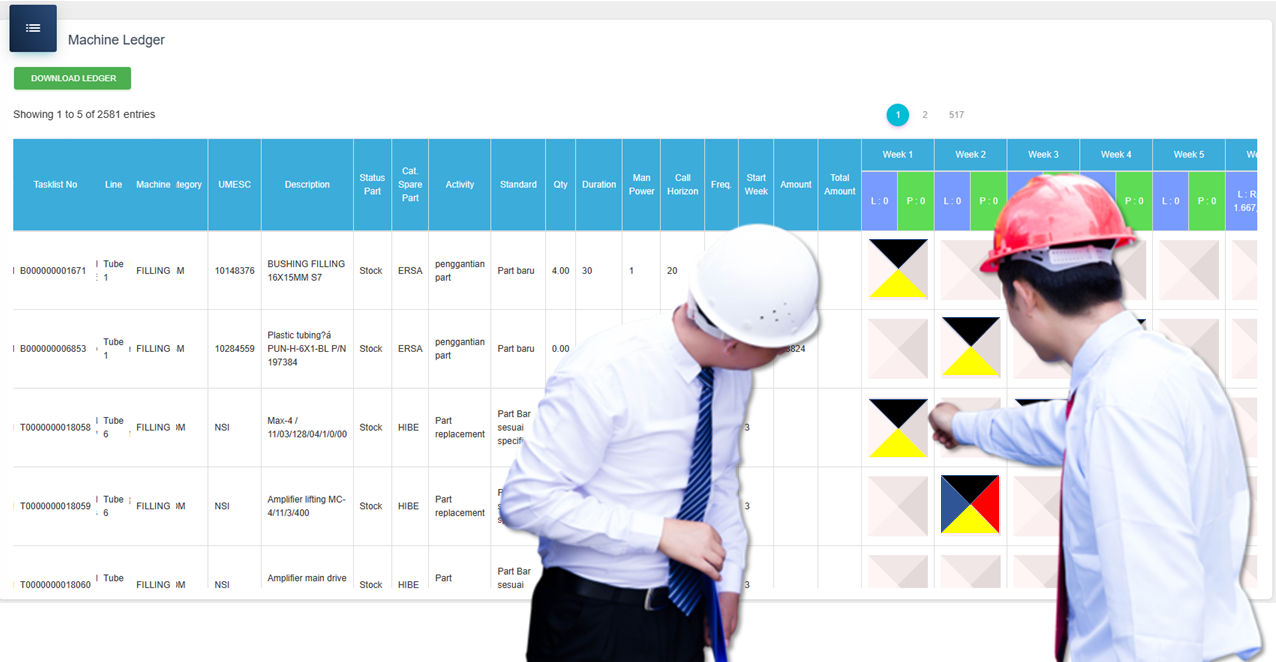

Cost and budget transparency between labour and spare part, defined by weekly or monthly periodical timelines

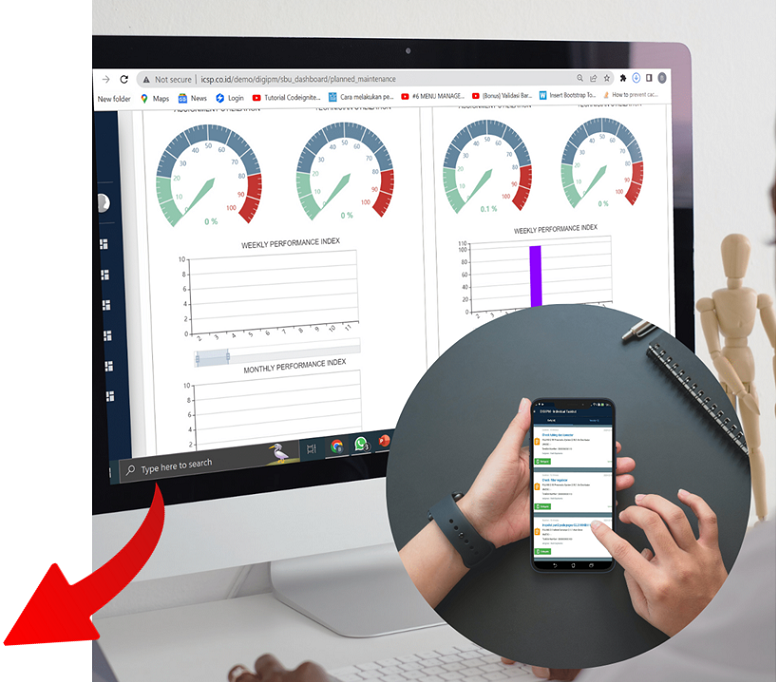

Easy to collaborate,manageable and fully consideration to user mobilities

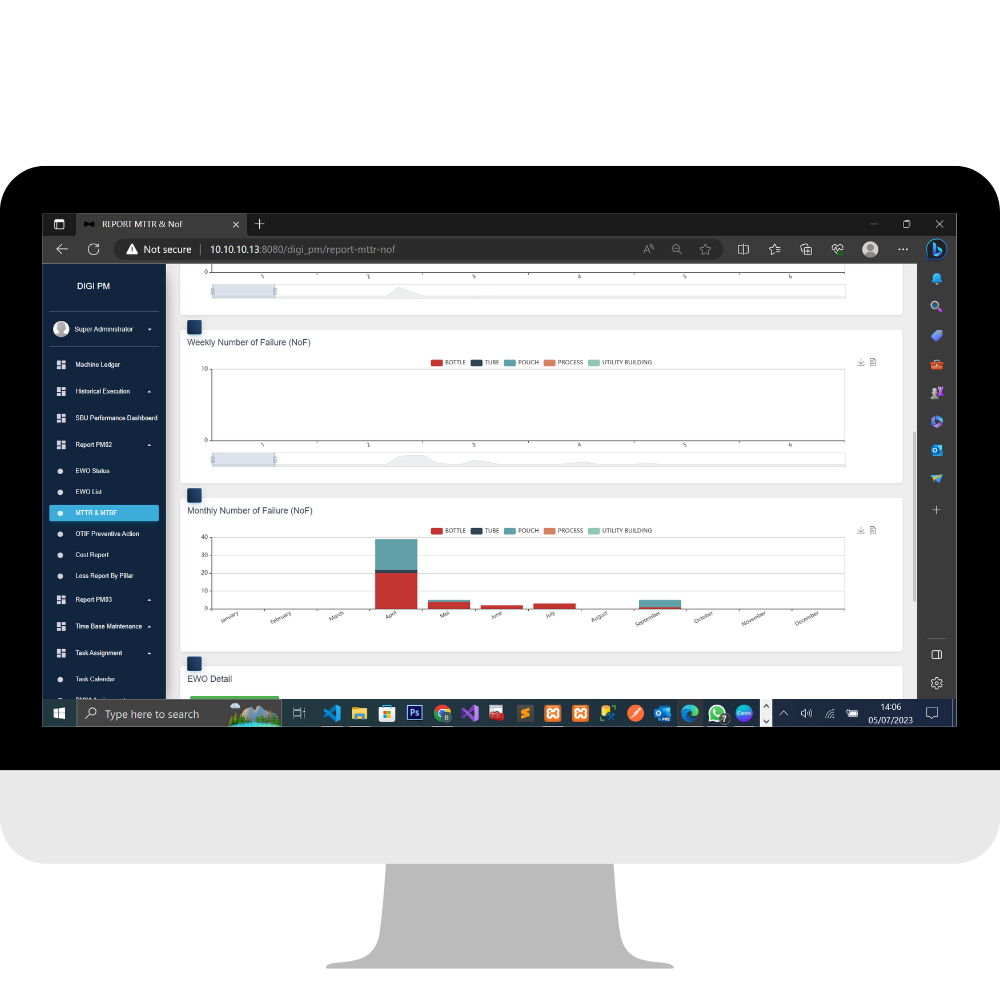

Simple ledger tools to effectively predict failures and plan preventive maintenance activities.

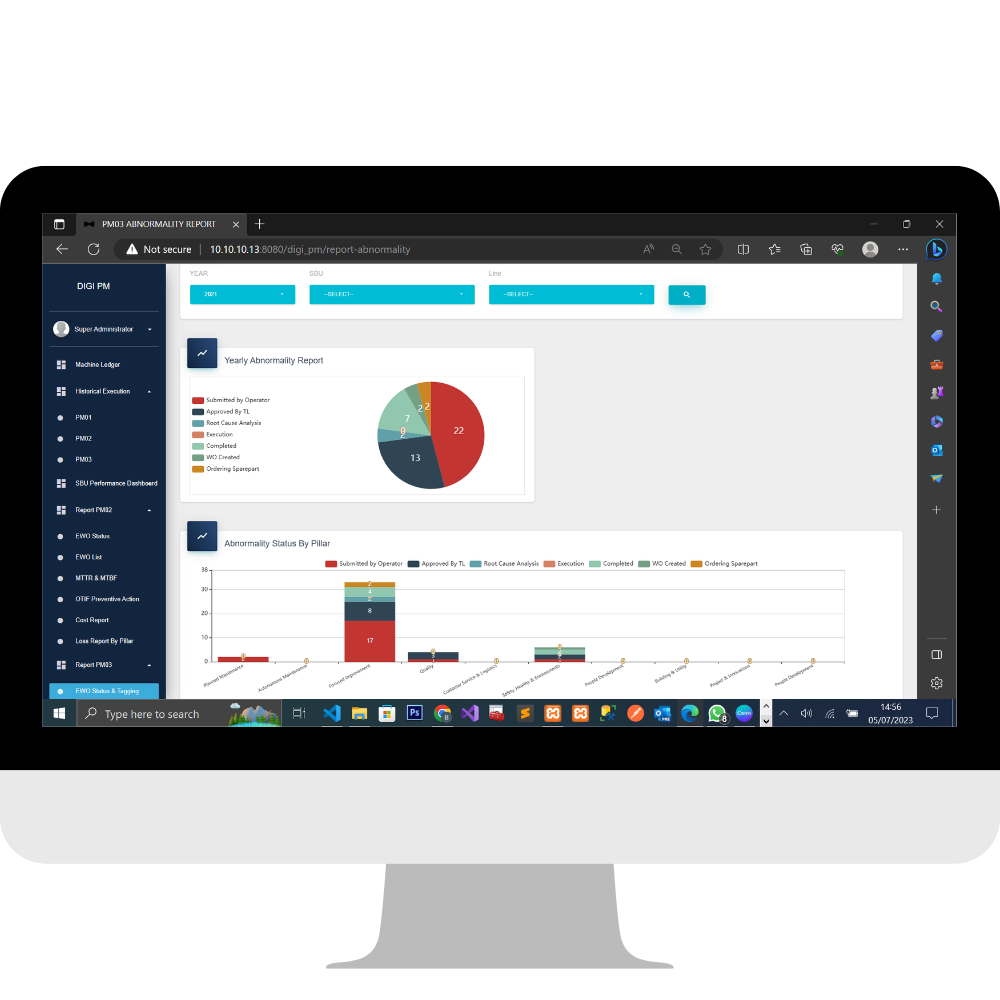

Empower frontline staff to maintain their equipment

Downtime at a busy plant can mean tens or hundreds of thousands of dollars of lost revenue perday.Yet most plants only have a small roster of trained technicians,whose time is in high demand.They’re expected to perform proactive and preventative,as well as reactive and corrective maintenance as problems a rise.

The promise of Digital Planned Maintenance [DIGIPM] System is simple : by empowering your operators to perform regular inspections and maintenance on your machines you will increase your productivity,profitability,andOverall Equipment Efficiency (OEE).At the same time you will transform your frontline staff from“button pushers and switch flickers” to true, engaged,partners responsible for the productivity of your machines and equipment